Cutting steel with a desktop CNC might sound ambitious, but it’s a common question for those diving into CNC machining at home. Desktop CNC machines are great for small-scale projects and often excel at handling softer materials like wood or plastic. But when it comes to CNC steel, things get a bit more complicated. Steel is a strong material that requires much more force, precision, and endurance from your CNC machine. That said, it doesn’t mean cutting steel with a desktop CNC is impossible. However, it’s crucial to know the limits of your equipment and understand adjustments to make it work. In this article, we will discuss whether a desktop CNC can cut steel, the factors involved, and what you should think about before taking on the challenge.

Can a Desktop CNC Cut Steel?

A desktop CNC can cut steel, but it’s not as straightforward as cutting softer materials like wood or plastic. While it’s possible, there are some key challenges that come with working on such a rigid material using a smaller, less powerful machine. Desktop CNCs don’t have the industrial-grade horsepower of larger machines, which means they may struggle to cut steel quickly or smoothly.

To make it work, you’ll need to make some adjustments. Steel is dense, so cutting it too fast will wear out your tools and stress the machine. You’ll need to use strong, durable cutting bits, preferably carbide or coated tools for hard materials. Since steel cutting generates a lot of heat, adding coolant or a misting system can help prevent overheating and tool wear. That said, even with all the proper adjustments, you should be prepared for the process to take longer than expected.

Here’s a detailed overview of both parameters to begin with:

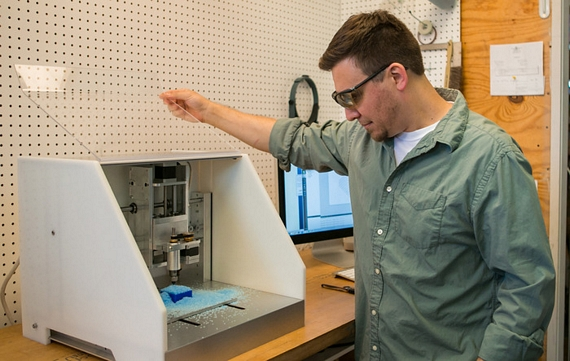

Desktop CNC

desktop CNC machine used to make scale model rims and wheels from plastic

Desktop CNC machines are compact, user-friendly versions of industrial CNC machines. Their main appeal lies in their size and affordability, making them accessible to small businesses. As such, they’re designed for small-scale projects and are often found in home workshops or maker spaces. These machines perform well with softer materials like wood, plastic, and aluminum.

However, being smaller also means having less power. Desktop CNCs typically run on lower power, which limits the types of materials they can handle effectively. Cutting steel, for example, pushes the machine to its limits. That doesn’t mean it’s impossible, but it does mean the machine will need to work harder, slower, and with the right setup to get the job done.

Steel

Steel is one of the most rigid materials out there compared to wood or plastic. It’s tough, durable, and much more challenging to cut through. That’s why it’s commonly used in the construction, automotive, and manufacturing industries. Steel can handle stress and wear that would quickly damage softer materials. But with all this strength comes the need for more power and precision when cutting it.

When cutting steel, you’re dealing with a material that puts more strain on your tools and machine. It requires sharp, tough cutting bits, and you must control the heat generated during the process to avoid damaging the tools. Also, steel comes in different grades, impacting how easily it can be cut. For instance, softer carbon steels are easier to work with than tougher alloys like stainless steel.

Key Considerations for Choosing a Desktop CNC to Cut Steel

Choosing a desktop CNC to cut steel requires careful considerations because not every machine is cut out for the job. Steel is one of the tougher materials to work with, so you need a machine that’s up to the task.

Below are the key factors to consider when deciding on the right desktop CNC for steel cutting:

Machine Power

Machine power is very vital when cutting steel. A powerful spindle motor, typically between 1.5 kW and 2.2 kW, is ideal for cutting steel. If the motor isn’t strong enough, you’ll notice the machine struggling, which can lead to poor cuts, overheating, and quicker wear on the machine. The thickness of the steel you’re cutting also plays a role in choosing the right CNC. If you’re cutting thinner steel sheets, lower power might work, but anything thicker will need that extra power boost.

Tooling Compatibility

You can’t just use any cutting tools when working with steel. Steel requires tough, durable tools like carbide bits or high-speed steel (HSS) that are built to withstand high heat and friction. Carbide tools, in particular, stay sharper for longer and can cut more efficiently through tough materials like steel. Also, you should ensure the desktop CNC you’re considering can handle these high-performance bits. Some machines are limited in what tools they support, so it’s best you check and confirm this.

Cooling System

Steel cutting generates lots of heat. Without proper cooling, your tools can overheat, become dull, and even break. You can also damage the workpiece itself if it overheats. Consider a desktop CNC that has or can be fitted with a cooling system, like a misting system or flood coolant, to keep the cutting tools and material from overheating. These systems spray coolant onto the cutting area, keeping both the tool and the steel cool. If your CNC doesn’t come with one, check if you can add it separately. This little addition can make a big difference in how long your tools last and the quality of your cuts.

Speed and Feed Rate Control

The ability to control your machine’s speed and feed rate is crucial when working with steel. If you cut too fast, you’ll risk damaging your tools and the machine itself. The key is controlling the speed of the spindle and the feed rate (how fast the tool moves through the material). Look for a machine that lets you adjust these settings, so you can dial them down when cutting steel and make precise, gradual cuts.

Rigidity and Build Quality

A lightweight or flimsy machine won’t stand up to steel cutting. If the machine’s frame isn’t sturdy enough, you’ll end up with shaky cuts and wear on both the machine and your tools. The more rigid the CNC frame, the less vibration you’ll have, which means better accuracy and cleaner cuts.

Software Support

Cutting steel requires more than just pushing “start” on your CNC machine. You’ll need software that allows for precise control over your cutting paths, tool changes, and other variables. Good software will let you optimize the process specifically for steel, including fine-tuning speed, feed rates, and tool positioning. Additionally, advanced features like simulation can help you test your settings before cutting, reducing mistakes and saving you time.

Advantages of CNC Shop Over Desktop CNC at Home

advanced CNC machines at the Zintilon factory

When it comes to cutting steel, there’s a big difference between using a desktop CNC at home and working with a full-scale CNC shop. While a desktop CNC machine can handle some smaller jobs, a CNC shop offers several benefits that just can’t be matched at home.

Let’s dive into why a CNC shop might be the better choice if you’re looking to cut steel with better results.

More Power and Precision

CNC machines in professional shops offer much better power and precision. Unlike desktop CNCs, which are limited by size and motor capacity, shop machines are built to handle heavy-duty tasks. They’re equipped with more powerful spindles, capable of cutting through thick steel more easily. And, because they’re designed for industrial use, these machines have much better accuracy. If you’re working on projects that require extreme precision, a CNC shop is the way to go.

Higher Production Capacity

A desktop CNC is great for one-off projects or hobby-level tasks. But if you need to produce multiple parts or work on larger projects, it’s going to be a slow process. CNC shops, on the other hand, are built for volume. They have larger machines that can run multiple operations at once, cutting down production time significantly. Plus, many CNC shops have automated systems in place, allowing them to work on several jobs at once without constant supervision. If you need faster production and can’t afford to spend hours cutting a single part, opt for a reliable CNC shop.

Better Material Handling

Handling large steel sheets or blocks can be a real hassle in a home workshop. You’re limited by space and besides, moving heavy steel around isn’t easy without the right equipment. CNC shops are fully equipped with cranes, material handlers, and larger cutting beds. This means they can easily handle big, heavy pieces of steel, which is nearly impossible with a desktop CNC. So if your project involves large parts, it’s safer and much more practical to let the professionals handle it.

Advanced Cooling and Tooling Systems

One of the biggest challenges with cutting steel is heat. Desktop CNCs at home often struggle because they lack the advanced cooling systems found in professional shops. CNC shops use high-end cooling setups like flood cooling or advanced mist systems to keep both the tools and the steel cool during the cutting process. This prevents overheating, extends the life of the cutting tools, and leads to a better finish.

Moreover, desktop CNCs at home are usually more basic, limiting what you can actually do with them. On the other hand, CNC shops have access to more advanced tooling and machines for various tasks. These range from 5-axis CNCs to specialized lathes and mills. Whether you need engraving, drilling, or intricate 3D shaping, a well-equipped CNC shop will handle the job more efficiently.

Skilled Technicians and Expertise

While desktop CNCs are designed to be user-friendly, there’s no substitute for years of experience. In a CNC shop, you have trained professionals who understand the ins and outs involved in cutting steel. They know which tools to use, how to set the perfect feed rate and speed, and how to troubleshoot any issues during the process. Having this expertise ensures that your project will come out exactly as you specify, without the trial and error that can happen when working at home.

Better Surface Finish

The quality of the surface finish is perhaps the key difference you’ll notice when comparing desktop CNC projects to those done in a shop. Professional CNC machines have higher resolution and more precise movement, which results in smoother, cleaner cuts. They also have access to quality finishing processes like polishing or even powder coating, ensuring your steel parts not only fit perfectly but also look great. While suitable for basic cuts, a desktop CNC might leave behind rough edges or less polished surfaces that require extra finishing work.

Conclusion

A desktop CNC can cut steel, but it comes with limitations. It can get the job done for small-scale projects and lighter cuts, especially if you don’t mind the slower pace. However, when it comes to handling tougher materials, delivering consistent precision, and speeding up production, a CNC shop is the smarter option. CNC machine shops have more powerful machines, skilled operators, and the right cooling systems to prevent overheating, ensuring better quality and faster turnaround. If you’re aiming for professional-grade results with steel, choosing a CNC shop offers clear advantages in efficiency, accuracy, and overall performance.

At Zintilon, we can handle all your steel-cutting projects. Skip the limitations of desktop CNCs and rely on our professional precision CNC machining services for unbeatable accuracy, quality, and efficiency. Reach out today and let us handle the heavy-duty work.