Types and Weights

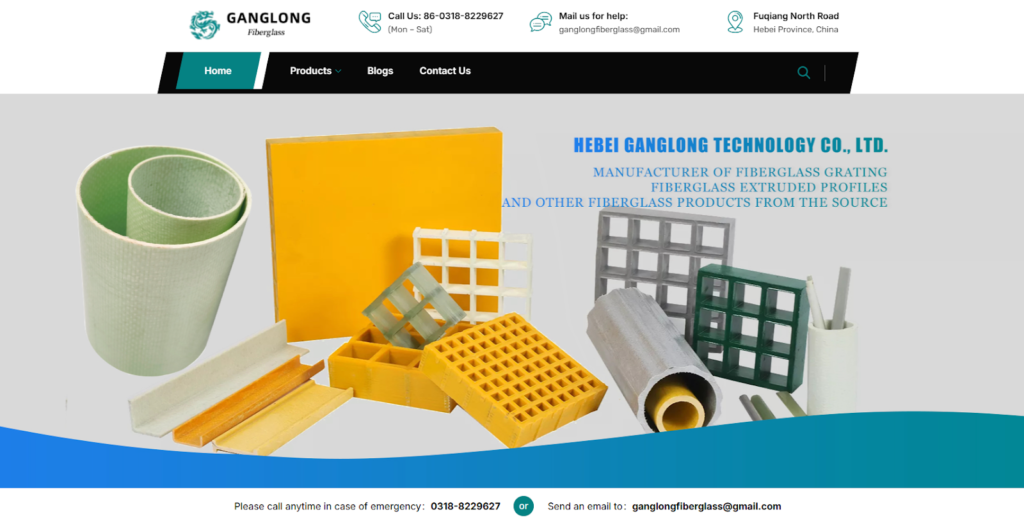

Chopped Strand Mat (CSM) is a fiberglass reinforcement material commonly used in composite manufacturing. Its versatility and strength make it ideal for a wide range of applications, including boat building, automotive parts, industrial products, and general fabrication. CSM consists of randomly oriented, short fiberglass strands held together by a resin binder. This structure provides a combination of strength, flexibility, and ease of use that is highly valued in composite construction. GangLong Fiberglass offers high-quality Chopped Strand Mat, providing a variety of options in terms of weight, size, and type, ensuring reliable performance for diverse industrial applications. Additionally, CSM can be used in conjunction with other fiberglass-based products, such as cable ladder, to enhance the performance and durability of complex industrial systems. Below, we will explore the different types, weights, and sizes of chopped strand mat, along with specific product options to guide users in selecting the most appropriate material for their needs.

Common Weights of Chopped Strand Mat

The weight of chopped strand mat directly affects its strength and thickness, which in turn influences its application. The following are the most common weights used in various industries:

- 0.75 oz per square foot: This weight is suitable for lighter applications that require thin laminates. It is typically used for smaller repairs or for applications where minimal thickness is required. It offers a flexible and lightweight material that bonds well with resin.

- 1.5 oz per square foot: The 1.5 oz per square foot mat is one of the most widely used weights in the composite industry. It strikes a good balance between strength and flexibility. This weight is suitable for a broad range of projects, from smaller parts to larger components, and is commonly used for boat hulls, automotive parts, and general composite construction.

- 2 oz per square foot: A 2 oz per square foot chopped strand mat offers increased strength compared to the 1.5 oz version. It is typically used in projects requiring greater durability, such as components that will experience significant stress, like structural parts of vehicles, large marine structures, or industrial equipment. This weight provides added thickness and is ideal for laminates that need to be both strong and flexible.

- 3 oz per square foot: This is one of the heaviest weights available for chopped strand mat and is designed for heavy-duty applications. It is ideal for applications that require substantial strength and thickness, such as large structural components, pressure vessels, or parts subjected to high impact and stress. The 3 oz mat ensures a strong, durable laminate that can withstand challenging environments.

Size Options for Chopped Strand Mat

Chopped strand mat is available in a variety of widths to suit different project needs. The choice of size depends on the dimensions of the project and how much coverage is needed. The most common size options for chopped strand mat include:

- 38 inches wide: This narrower width is often used for smaller projects, such as small repairs or parts that do not require extensive coverage. It allows for easier handling and cutting, making it ideal for precise applications.

- 50 inches wide: The 50” wide roll is one of the most versatile sizes, providing a good balance of material coverage and flexibility. It is commonly used in a variety of composite applications, from small to medium-sized parts, and is often the preferred choice for boat building, car body parts, and other industrial applications. Fiberglass sheets can be combined with this size to create stronger, more durable structures, especially for parts that need additional rigidity or surface smoothness.

- 60 inches wide: This width is used for large-scale applications where a significant amount of material is needed. The 60” roll provides excellent coverage for bigger surfaces or larger components, making it ideal for industries that require large pieces, such as marine, aerospace, or heavy machinery manufacturing.

Types of Rolls Available

Chopped strand mat can be purchased in different forms to suit the specific requirements of a project. These include full rolls, slit rolls, and pre-cut lengths, each offering unique benefits:

- Full Rolls: Full rolls are typically available in standard widths of 50” or 60” and are ideal for larger projects where continuous material is required. These rolls are the most cost-effective for extensive applications and can be used for large laminates or structural parts that require large surface areas of chopped strand mat.

- Slit Rolls: Slit rolls are narrower rolls that have been cut down to specific widths. These are perfect for projects where a specific width is needed or for applications that do not require full-width rolls. Slit rolls are often more convenient for precise, smaller jobs and can be easier to handle than full rolls.

- Pre-Cut Lengths: Pre-cut lengths of chopped strand mat are ideal for smaller projects where convenience and time-saving are priorities. These lengths come in specific dimensions, such as 1-foot or 2-foot sections, making them a convenient choice for users who do not need to cut the material themselves.

Specific Products

Several specific types of chopped strand mat are available based on weight, size, and surface finish:

- Chopped Strand Mat 1.5 oz x 50” wide: This product is a common choice for general-purpose applications. It provides a good balance between weight and coverage, making it suitable for everything from boat hulls to automotive parts. Its versatility makes it a popular option in many industries.

- Chopped Strand Mat 2 oz x 60” wide: With a heavier weight and wider width, this option is suitable for applications that require added strength and larger coverage. It is often used in more demanding applications where the laminate needs to be thicker and more robust, such as structural components in industrial equipment or large marine vessels.

- 20 ml Surface Veil: The surface veil is a thin layer of fiberglass mat used as a top layer to provide a smoother, more aesthetically pleasing finish. It is commonly used in cosmetic applications where the surface of the composite must be flawless. The 20 ml surface veil ensures a high-quality finish, ideal for parts that will be visible or require a smoother surface for further coating or finishing.